PROSTHETIC & ORTHOTIC INDUSTRY

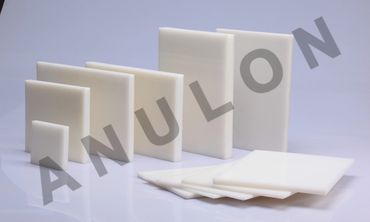

PLASTIC SHEET FOR ORTHOTICS & PROSTHETICS

ABOUT

Our Health care business involves manufacturing of Our

- ANULON 92 OPG (P)

- ANULON 92 OPG+ (P)

- ANULON 98 OPG (H)

- FLEX- O

- SUPER FLEX-O

These sheets is used for making appliances for orthosis and prosthesis application and Anulon Patrans used in hospitals and patient transfer application. Since Plastic Abhiyanta has been established with a state of the art plant we manufacture and supply these sheets to cater to the specific need of this sector with use of specified grade of raw materials and further compounded with special additive to enhance the strength and forming properties of the sheet and to deliver precisely world class end products.

We are Asia's only company to make such vast variety of sheets under one roof.

Apart from the above mentioned sheets, we are also into manufacturing of ancillary products for this industry.

ANULON 92 OPG (P)

More about the Product

Our Premium Grade Polypropylene sheet is made to a specification set by international standards that takes into consideration the challenging nature of manufacturing in the prosthetics and orthotics profession. The material is designed to drape evenly avoiding excess thinning, which can lead to rejection of the formed device. Customers have a common question about PP sheets, that is shrinkage, with Anulon 92 OPG (P) it's not a problem. An independent study measured the shrinkage by volume of our Anulon 92 PG (P) is less than 1%, a standard that is hard to match.

Anulon 92 OPG (P) consists of mainly Polypropylene with a small amounts of special additives to enhance the quality, it is this combination that imbues Copolymer Polypropylene with its unique ability to resist fatigue when flexing under load. In orthotics, this feature makes Copolymer Polypropylene particularly suitable for AFO's (Ankle Foot Orthosis), KAFO's (Knee Ankle Foot Orthosis) and DAFO's (Dynamic Ankle-Foot Orthosis).

Copolvmer Polypropylene is also used to make TLSO's ( Thoraco Lumbar Sacral Orthosis - Thoracolumbarsacral orthosis), where a balance of flexibility and rigidity has to be achieved.

In prosthetics, Copolymer Polypropylene has been widely used to make BK (Below Knee) and AK (Above Knee) sockets with great success. The ability to make a socket quickly and cleanly is appreciated, as is the fact that minor adjustments can be quickly and easily made, without risking the mechanical integrity of the socket.

Features

- Light weight

- Versatile

- Rigid

- High impact strength

- Maintains impact strength down to -20°C / - 4°F

- Has the ability to constantly flex without fracturing

- • Shrinkage of <1% (by volume)

Available in the following thickness

2mm, 3mm, 4mm, 5mm, 6mm, 8mm, 10mm, 12mm & 15mm

Tolerance in thickness : ± 5%

Colour

Natural & Skin

Other colours can be made against bulk order.

Sheet size

1mtr x 2mtr

1.25mtr x 2mtr

1.5mtr x 2mtr

1.05mtr x 2.1mtr

1.25mtr x 2.1mtr

**Custom size against bulk order

Moulding Temperature

Orthotics - 180° - 200°C / 356°- 392°F

Prosthetics - 200°- 220°C / 392°-428°F

ANULON 92 OPG (P) +

More about the Product

Made from 100% imported material, Anulon 92 OPG+ offers greater rigidity than conventional PP sheets.

Anulon 92 OPG+ is a thermoplastic sheet material that uses copolymerisation to combine the good properties of polypropylene and the toughness of polyethylene.

The polypropylene used in Anulon OPG + obtained in this way shows considerably increased impact strength in comparison with a homopolymer polypropylene or conventionally used PP sheets, especially at low temperatures. The Anulon 92 OPG+ is easily thermoformed and heat-sealed and is ideal for placing around orthotic joints.

ALL OUR OPG+ GRADE HAS ANTI MICROBIAL & ANTI ODOUR FEATURES

Features

- Light weight

- Versatile

- Rigid

- High impact strength

- Maintains impact strength down to -20°C / - 4°F

- Has the ability to constantly flex without fracturing

- • Shrinkage of <1% (by volume)

- ANTI MICROBIAL

- ANTI ODOUR

Available in the following thickness

2mm, 3mm, 4mm, 5mm, 6mm

Tolerance in thickness : ± 5%

Colour

Natural

Other colours can be made against bulk order.

Sheet size

1mtr x 2mtr

**Custom size against bulk order

Moulding Temperature

Orthotics - 180° - 200°C / 356°- 392°F

Prosthetics - 200°- 220°C / 392°-428°F

ANULON SUPER FLEX

More about the Product

The good flexibility and transparency of Anulon SuperFlex sheet are especially useful for fabricating flexible inner prosthetic sockets. The natural-coloured (translucent) material is used mainly inner lining. The material's benefits are high surface quality and wearer comfort. Anulon Super Flex sheet have proven to be excellent choices for highly flexible transfemoral soft-walled inner sockets. This material is a thermoplastic which exhibits a higher shrinkage if the cooling rate is too high.

Features

- Highly Flexible

- Good Impact Strength

- Higher shrinkage due to its molecular structure

- Versatile usage

Available in the following thickness

2mm, 3mm,6mm, 8mm & 10mm

Tolerance in thickness : ± 5%

Colour

Natural

Sheet Size

1.25mtr x 2mtr

Moulding Temperature

Orthotics & Prosthetics - 120°- 150°C / 248°-302°F

ANULON FLEX-O

More about the Product

ANULON FLEX-O is a soft, flexible material used mainly in orthotic applications. The combination of flexibility and a degree of rigidity makes it a popular choice of material in the manufacture of TLSO braces. It can also be used to make wrist splints, neck braces & resting splints.

An issue to be noted with any Low Density Polyethylene (LDPE) is susceptibility to attack by human skin oil.

This affects the material by attacking the surface and weakening the material. Where the material is under stress, small cracks, or crazing will appear and the material will eventually fail. The degree to which the material is exposed to human skin oil will obviously affect the outcome.

Anulon Flex-O is made using a specific polymer keeping in mind international standards, and extruded very carefully to minimise the level of shrinkage that affects the material. Team Plastic Abhiyanta guarantees that our Anulon Flex-O will shrink by no more than 6% (area) when heated at our recommended temperature.

Other extruded LDPE sheet can shrink by up to 30% (area).

Features

- Semi flexible

- Good impact strength

- Maximum shrinkage 6%, guaranteed when heated at the correct temperature

- Affected by skin oil exuded in sweat, can lead to stress cracking

Available in the following thickness

3mm, 4mm, 5mm, 6mm, 8mm, 10mm & 12mm

Tolerance in thickness : ± 5%

Colour

Natural

Sheet Size

1.5mtr x 2mtr in all thickness

1.05mtr x 2.1mtr & 1.25mtr x 2.1mtr in 6mm only

Moulding Temperature

Orthotics & Prosthetics - 150°C / 302°F

Photo Gallery

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.