ANULON 94 ULTRA HIGH MOLECULAR WEIGHT POLYETHYLENE / UHMWPE

ANULON 94 ULTRA HIGH MOLECULAR WEIGHT POLYETHYLENE / UHMWPE

Plastic Abhiyanta offers a superb selection of UHMWPE sheet with excellent sliding properties. Ultra high molecular weight polyethylene is known as UHMWPE for short or PE1000 due to its molecular weight. UHMWPE has outstanding abrasion resistance, non sticking, excellent mechanical properties and superior impact strength, even at temperatures below -200°C. These excellent properties means UHMWPE is used for food and beverage machinery, bulk material handling, chemical and mining processing equipment and much more. UHMWPE can be machined into virtually anything from gears, bearings to large sprockets. This PE1000 grade plastic can even outperform steel in sliding applications because of its low coefficient of friction. The product is often regarded as uhmw sheets.

Available in

RODS

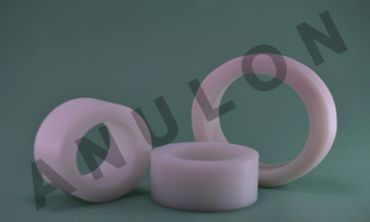

COMPONENTS

SHEETS

SHEETS

COMPONENTS

SHEETS

COMPONENTS

COMPONENTS

COMPONENTS

LINERS

WEAR RESISTANT PLATES

COMPONENTS

GUIDE PLATES

WEAR RESISTANT PLATES

WEAR RESISTANT PLATES

WEAR RESISTANT PLATES

WEAR RESISTANT PLATES

WEAR RESISTANT PLATES

PRESSURE PADS

PRESSURE PADS

PRESSURE PADS

Photo Gallery

Technical Data

Mechanical Properties

Thermal Properties

Electrical Properties

Other Properties

Downloads

ANULON 94 LINERS

ANULON 94

Anulon 94 is lining material that is used to reduce flow problems of bulk solids in bins, hoppers, chutes, truck beds and bulk material handling for the Mining Industry, Iron and Steel Industry, Aluminium Industry, Cement Industry or any other industry handling abrasive material.

The special range of Anulon 94 solves problems of friction, wear and flow of materials.

Benefits include:

- Very High Impact Strength

- Exceptionally low friction

- Temperature resistance: -40°C up to +82°C

- Low water absorption

- Chemical Resistant

- Wear and abrasion resistant

- UV Stability

- High Operating Temperature

- Economic Advantages

- Lower Cost for lining an existing bin is about one third of the cost of construction steel

- Lower Weight -a reduction in weight of almost three tons compared to standard method of welding steel sheets. The reduced load of the structure makes installation simpler.

- Longer Life span – In the sand slurry test Anulon 94 is significantly longer than conventional steel.

- Reduces the risk of arching and changeable material flow.

Applications

Traditional steel surfaces become corroded causing the bulk material to stick to the steel. Changes in moisture and particle size affect the products flowability

Anulon 94 is used in a variety of industries that handle bulk materials from Mining up to the final processing or use of the product at the factory.

Given below points help you understand this better

Applications

PROCESSING

STORAGE AND HANDLING

STORAGE AND HANDLING

- Day bins

- Surge bins

- Batch hoppers

- Storage silos and bins

- Hoppers

- Chutes

- Feeders

- Screw conveyors

STORAGE AND HANDLING

STORAGE AND HANDLING

STORAGE AND HANDLING

- Silos, bins, bunkers

- Reclaim hoppers

- Truck dump hoppers

- Rail dump hoppers

- Vibratory feeder pans

- Receiving Hoppers

- Dozer blade liners

- Slider beds

- Skirting

- Belt scrapers

TRANSPORTATION

STORAGE AND HANDLING

BULK MATERIALS HANDLED

- Ship holds

- Railcars

- On-road truck bed liners

BULK MATERIALS HANDLED

BULK MATERIALS HANDLED

BULK MATERIALS HANDLED

- Coal

- Iron ore

- Copper concentrate

- Clay

- Limestone

- Soda Ash

- Chemical Powders

- Nickel Ore

- Synthetic Gypsum

- Peat

- Kaolin Clay

- Potash

- Salt

- Silica Sand

- Soap Detergent

- Wood Chips

- Zinc Concentrate

- Phosphate

- Dust

- Talc

MINING

BULK MATERIALS HANDLED

MINING

- Off-road truck bed liners

- Shovel liners

- Hopper liners

- Chute liners

- Scrapers

- Dragline bucket liners

- Stacker/ Reclaimer bucket liners

- Front-end loader buckets

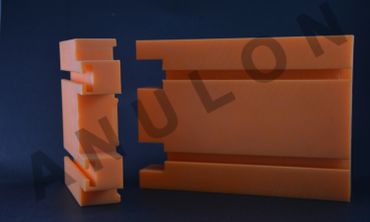

ANULON 94 CHAIN GUIDE PLATE / GUIDE LINERS

ANULON 94 CHAIN GUIDE PLATE / GUIDE LINERS

ANULON 94 GP

Anulon 94 products used in plant and machinery used in conveyor and material handling technology, the storage and packaging industry and the bottling and beverage industry rely on thermoplastic components. Extruded profiles are a key part of these. They are used wherever good slide characteristics are demanded alongside high wear and abrasion resistance. With more than 700 different cross- sections now available, Plastic Abhiyanta offers what is probably the widest selection of Anuon 94 profiles on the market. Whether you need cover- or clip-profiles, Z-, L-, U-, C-, T- or square- profiles, complex geometries, special surface structures or thin wall thicknesses, you can choose from the most extensive range of extruded standard profiles or special profiles customised just for you. Our experienced team will provide comprehensive advice to help you select the right cross-section.

The profile extrusion process

In profile extrusion, the raw material – a powder mixture of Anulon 94, additives and colouring pigments – is forced through a heated tool under high pressure. The material becomes plastic and takes on the form of the tool. After leaving the tool, controlled cooling is essential in order to equalise internal stresses and prevent the profile warping. The material expands at high temperature and then contracts again as it subsequently cools down. This means it is particularly important to configure the tool precisely so that the form and prescribed tolerances are kept in the finished profile.

Anulon 94

Is a material with exceptionally properties. As an extruded profile, this polyethylene of ultrahigh molecular weight solves problems of friction, wear and material flow in countless technical applications. Modern conveyor and material handling technology, storage and packaging systems and the bottling and beverage industry could not do without this high-performance material today.

Outstanding slide characteristics

Their low slide friction coefficients enable extruded profiles made of Anulon 94 GP to reduce the drive energy required in conveyor systems and increase the stability of processes. Anulon 94 GP also has particularly long-lasting self-lubrication properties. Extreme wear resistance/ long service life Extruded profiles made of Anulon 94 GP can withstand high long-term stresses thanks to their extremely high wear resistance. Continuous operating temperature from -250 to +80° Celsius Extruded profiles from Plastic Abhiyanta are used in a large number of applications involving high and very low temperatures, such as spiral frosters or cold stores.

Environmentally friendly 100% recyclable

Suitability for use with foods already available for many recipes

High impact strength

Various Profiles

Contact Us

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.